MASTER GOMMONI

The origins of Master come from the great passion for the sea of its founders, the Gargiulo spouses , who began this journey in the 70s in Segrate (Milan). Their first work experience was in the service industry, and focused on the manufacturing of neoprene tubes for almost all the oldest companies of the nautical sector. Then, in 1983 they founded their own company, Master, and a few years later obtained the Master patent with the ” Magnum ” version.

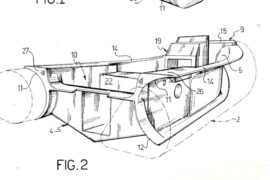

When the use of fiberglass reached the marine industry, the company created a special double molded hull with a fiberglass floor decking in the tubes, which allows a better balance of the overall structure, avoiding a stern-loading and thus allowing a dry and smooth navigation even in rough sea.

In 1997, when the company was already ranked among the best Italian brands, Pietro Gargiulo decided to move back to his birthplace, Palermo, whith his family and the company… finally on the seaside.